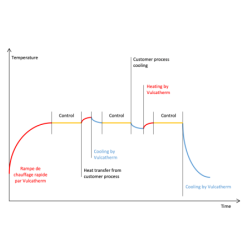

Vulcatherm temperature control unit Hot/Refrigerated for heating, cooling and regulating a closed loop of glycol water from -20°C to 90°C max intended for crystalizers, chemical reactors, climatic chambers, test benches, etc. Power heat 10 kW / 400 V 3P + E. Cooling by integrated refrigerating unit and exchanger/condenser supplied by the customer's industrial water network. Atmospheric expansion of the medium. max admissible pressure of 10 bar.g in the circuit.

The Vulcatherm temperature control unit consists of:

- 1 Electrical heater with temperature sensors

- 1 Pump

- 1 Evaporator exchanger

- 1 condenser water cooled

- 1 Refrigerating compressor

- 1 Atmospheric expansion tank

- 1 Electrical cabinet with integrated Central Management System

- Sensors for control and safety

in a painted frame equipped with castors